Who We Are

Our Services

Design, Research & Development

Be unique in this ever-changing world with your own products with our help.

1. Product and Process design validation

2. Design consultation that emphasizes on easy and effective mold design, reduced maintenance efforts and consistent quality

3. Mold simulation Services

4. Prototyping

Tooling & Die Design

Create custom parts and make them fit with your system.

1. Experienced mold design and makers team. Precision tooling and machining expertise

2. 2d/3d design and mold flow validation for customer pre-evaluation

3. Design focusing on shortest lead time with maximum output

4. Software:

a. Solid works 2018

b. Moldex3D

c. DraftSight Premium

OEM or Contract Manufacturing

We are to be equipped with multiple state of the art latest tech machinery and facilities that are capable of large scale and multi-variety manufacturing. Our manufacturing process is carried in a controlled room environment to ensure and maintain deliverables quality.

We provide our customers a complete One-Stop Solution.

Measurement and QC Tools

We are to be equipped with multiple state of the art latest tech machinery and facilities that are capable of large scale and multi-variety manufacturing.

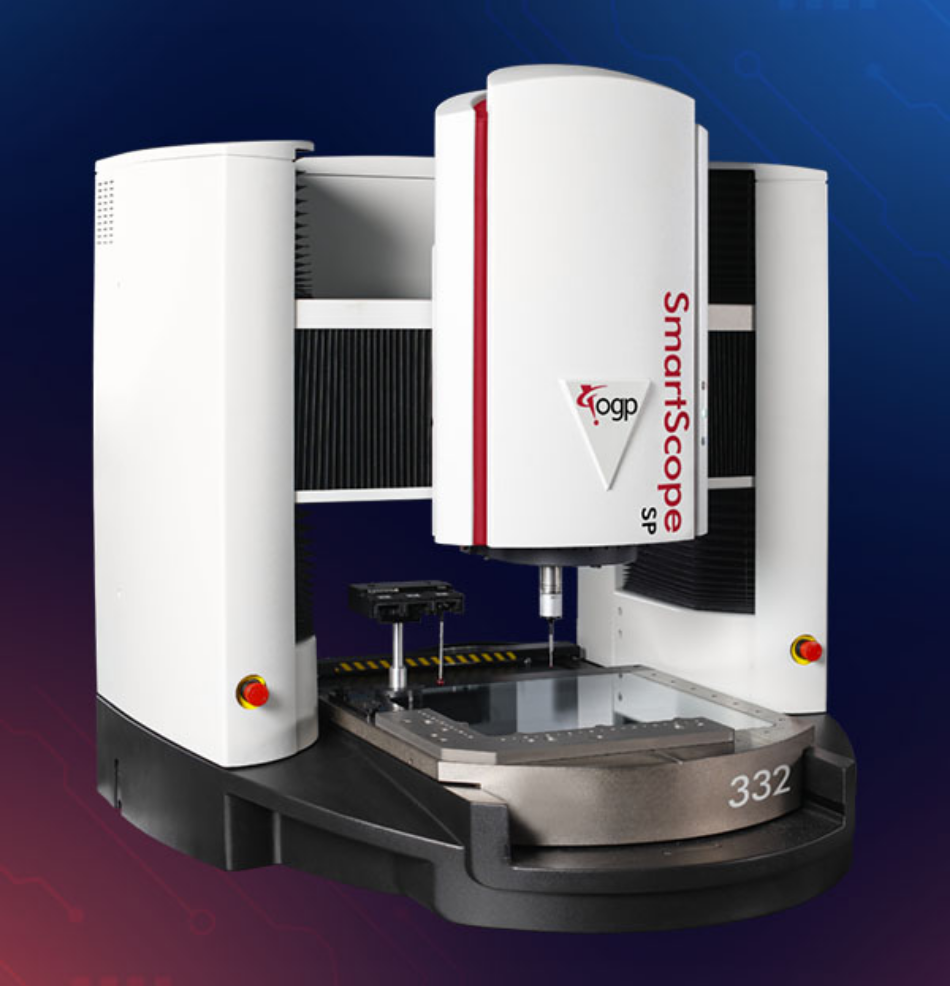

01.

Smart Scopes

The smart scope offers a precision visual inspection and measurement station. A microscope camera is used to view the sample on the stage. Features can be measured using precisely controlled motors which move the stage and feed their position back to the computer.

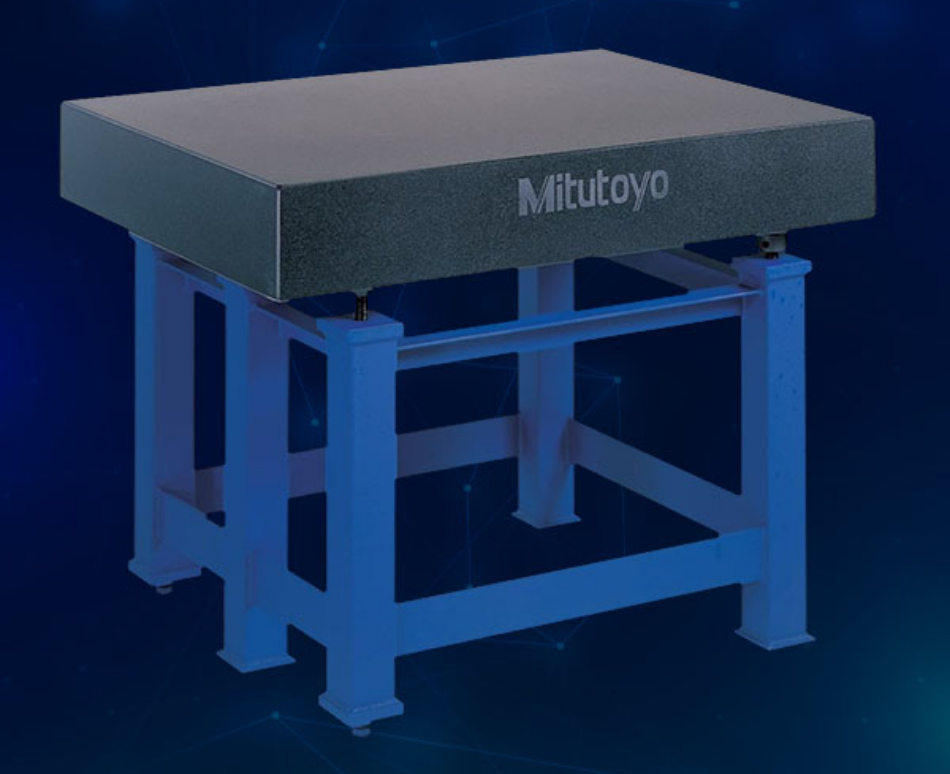

03.

Surface Plate

Serving as the baseline for all measurements, surface plates play a vital role in quality control. The surface is required to be extremely flat with accuracy up to 0.00001 inches or 250 nm for grade AA or AAA plates. Surface plates often check and zero out other pieces of equipment, so accurate and precise measurements are imperative.

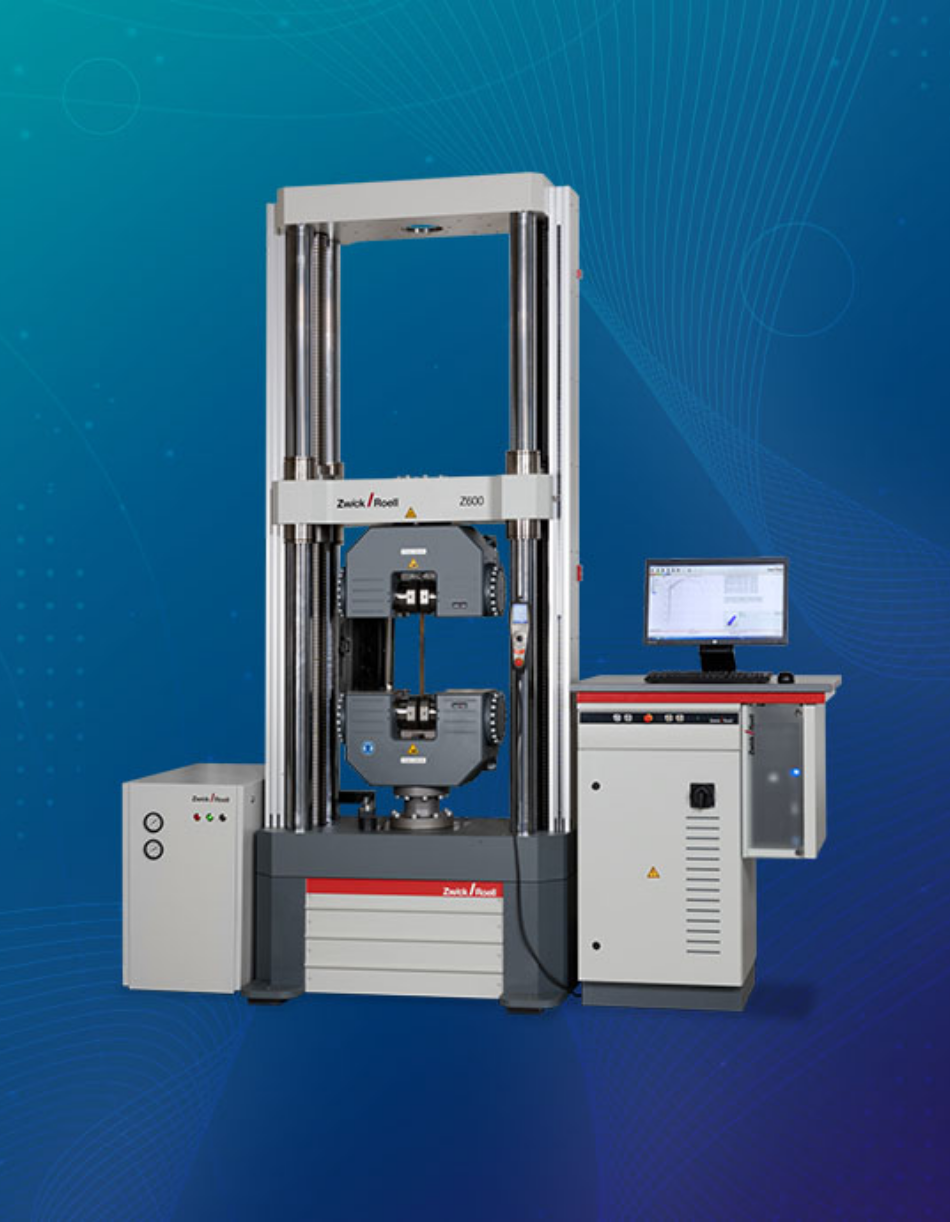

02.

Tensile Testing Machine

Our tensile testers will measure characteristics such as ultimate tensile strength, yield strength, elongation, and modulus. Each tensile test machine is configured to your testing needs by our application engineers with the correct controller, grips, and accessories.

04.

Precision Measurement Instruments

Among the array of precision equipment we have are micrometers, calipers, height gauges, taper gauges, and others.

Precision instruments measure variations as low as 0.001 millimeters, or 10 microns. Specialised equipment allow us to go even smaller.

We're The Best At What We Do

Injection molding – especially medical devices – requires specialty and experience.

Why Agile Medical Devices?

We always believe that more hands are better than one. We have partnered with industry leaders in their respective fields in order to successfully set-up the factory ready for operation.

2

Partners

Our strategic friends are CM Machinery Sdn. Bhd., the sole distributor of Haitian Machines for Malaysia, as well as Age Group Consultancy, our ISO consultant.

9

Services

From design and R&D to OEM and contract manufacturing – our services encompass a multitude of demands when it comes to medical devices.

4

Certifications

Agile as an organization considers certification and qualification documents as crucial elements that proves our capability and commitment.

Reach Out To Us

Fill out the form below and we will contact you within 1-2 business days.

With our in-depth experience, knowledge, skill and expertise, Agile Medical Devices Sdn. Bhd. is able to provide our customers a complete One-Stop Solution buying experience – from product conceptualization to its final product manufacturing.

Talk To Us

Visit

No 5, Jalan Perusahaan 11, Kawasan Perusahaan Kamunting, 34600 Kamunting, Perak

202101030843 (1431143-H)

Registration Date: 23 September 2021